Best Warehouse Management Systems of 2024: For Australian Businesses

09 Oct 2024

|by diadmin

In the fast-paced world of ecommerce and logistics, efficiency is key. A robust Warehouse Management System (WMS) can transform your operations, optimise warehouse operations, boost productivity and streamline processes. Selecting the right WMS ensures your warehouse runs like a well-oiled machine, reducing errors and improving customer satisfaction. In this listicle, we’ll explore the best warehouse management systems of 2024 and help you find your perfect match.

What is a warehouse management system and how does it work?

A Warehouse Management System (WMS) is a software solution crafted to enhance and efficiently oversee warehouse operations. It facilitates the smooth movement and storage of inventory, ensuring that goods are received, put away, picked, packed, and shipped efficiently and accurately. Here’s how a WMS works in detail:

- Inventory Management: A WMS helps track inventory levels in real time, provides accurate data about stock availability, and supports inventory control. It supports inventory audits and cycle counting, reducing errors and discrepancies.

- Receiving and Putaway: When goods arrive at the warehouse, the WMS records the receipt of items, verifies quantities, and updates inventory records. It also directs the putaway process, suggesting optimal storage locations to maximize space utilization.

- Order Fulfillment: The system manages order picking, packing, and shipping processes. It generates pick lists, optimizes pick paths, and ensures that orders are filled correctly and shipped to the right destination.

- Labour Management: A WMS can track workforce productivity by monitoring the time taken to complete tasks. It helps in planning labour resources, assigning tasks, and evaluating employee performance.

- Warehouse Layout Optimization: By analyzing data on inventory movement and storage patterns, a WMS can suggest improved warehouse layouts to enhance operational efficiency.

- Reporting and Analytics: The system generates detailed reports and analytics on various warehouse activities, providing insights into performance metrics, inventory turnover, and order accuracy.

- Integration: A Warehouse Management System (WMS) can seamlessly connect with other platforms, such as Enterprise Resource Planning (ERP) and Transportation Management Systems (TMS), to ensure a smooth flow of information throughout the supply chain.

Overall, a Warehouse Management System plays a crucial role in improving the accuracy, efficiency, and productivity of warehouse operations, ultimately leading to cost reduction and enhanced customer satisfaction.

Importance of Warehouse Management in Australian Businesses

Warehouse management plays a pivotal role in the success of Australian businesses, particularly those in the e-commerce and retail sectors. Effective warehouse management enables companies to streamline their operations, reduce costs, and enhance customer satisfaction. A well-managed warehouse ensures that inventory is accurately tracked, orders are fulfilled efficiently, and products are delivered to customers on time.

In Australia, where the e-commerce market is experiencing rapid growth, the importance of robust warehouse management cannot be overstated. With the surge in online shopping, businesses must manage their inventory and fulfil orders quickly and accurately. A warehouse management system (WMS) can be a game-changer for Australian businesses, providing real-time visibility into inventory levels, automating warehouse processes, and improving order fulfilment accuracy. By leveraging a WMS, businesses can optimize their warehouse processes, reduce errors, and ultimately deliver a superior customer experience.

Different Types of Warehouse Management Systems

Warehouse management systems (WMS) are available in diverse types, each tailored to suit different operational scales, technological requirements, and business environments.. Here’s a breakdown of the common types of warehouse systems, including descriptions, pros, cons, and typical use cases for each:

1. Standalone Warehouse Management Systems

These are your basic WMS solutions focusing mainly on warehouse tasks. They don’t come integrated with other systems like ERP or CRM right out of the box.

- Pros: Budget-friendly and easy to set up; great for small operations with straightforward needs.

- Cons: Limited features; lack of integration might cause data silos.

- Use Cases: Perfect for small warehouses or businesses looking for simple inventory management without needing to tie into other business processes.

2. Integrated Warehouse Management Systems

These WMS solutions are part of a bigger package of business apps, often inside an ERP system. They allow seamless data sharing across different business functions.

- Pros: Fully integrated with financial, HR, procurement, accounting software, and more; everything’s in one place.

- Cons: Costs more and can be trickier to set up and keep running.

- Use Cases: Best for medium to large businesses that need comprehensive management beyond just the warehouse.

3. Cloud-Based Warehouse Management Systems

Hosted on the vendor’s cloud, you can access these systems via the internet, typically on a subscription basis.

- Pros: Lower initial costs, scalable, easy updates and maintenance, and you can access it from anywhere.

- Cons: You need good internet, there are ongoing subscription costs, and there might be data security concerns.

- Use Cases: Great for businesses of all sizes wanting flexibility and scalability without heavy IT investments.

An example of a cloud-based WMS is the Oracle Warehouse Management Cloud, which enhances inventory visibility and fulfillment efficiency across various industries.

4. Supply Chain Modules

These WMS solutions are part of a supply chain management system, handling logistics from manufacturer to consumer.

- Pros: Gives you an integrated view of supply chain operations with enhanced logistics features.

- Cons: Can be complex and pricey and may need lots of customization.

- Use Cases: Ideal for bigger companies managing large-scale logistics and needing tight integration with supply chain partners.

5. Enterprise Resource Planning (ERP) Modules

ERP systems with built-in WMS features offer a holistic approach to managing all enterprise resources.

- Pros: Deeply integrated with other ERP modules (financial, HR, sales), providing a single source of truth for enterprise data.

- Cons: High cost, complex to implement, and might be overkill for businesses with simple warehouse needs.

- Use Cases: Large businesses with varied operations that benefit from integrated management across departments.

6. Custom-Built Warehouse Management Systems

These are tailor-made systems designed to meet the unique needs of a business.

- Pros: They’re made to fit specific operational needs perfectly.

- Cons: Costly, take longer to set up, and need ongoing maintenance.

- Use Cases: Perfect for enterprises with unique requirements not met by standard solutions, or those with the resources to invest in custom systems.

Factors to Consider When Choosing a WMS

Scalability

Your business is bound to grow, and so should your Warehouse Management System (WMS). A scalable system ensures that as your operations expand, your WMS can handle increased volume and complexity without missing a beat.

To achieve this, consider investing in a WMS that offers modular features, allowing you to add functionalities as needed. Regularly review your operational needs and assess whether your current system supports them effectively. Additionally, provide ongoing training for your staff to ensure they can fully utilize the capabilities of your WMS. This proactive approach will keep your operations running smoothly as your business evolves.

Compatibility

A seamless integration with existing hardware and software is crucial for operational efficiency and consistency. When selecting a Warehouse Management System (WMS), ensure that it can easily sync with your current systems, such as Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and e-commerce platforms.

This connectivity is vital to maintaining a unified workflow, minimizing disruptions, and enhancing data visibility across all departments. By achieving this level of integration, you can streamline processes, improve accuracy, and ultimately boost overall productivity.

Feature Set

Start by evaluating basic warehouse management functionality such as inventory tracking and order management, which are crucial for maintaining efficiency and organization. Beyond these basics, consider integrating advanced options to enhance your operations further.

Automation can streamline repetitive tasks, reducing manual effort and minimizing errors, while real-time analytics provide immediate insights into your business performance, enabling data-driven decision-making. By understanding and implementing these features, you can ensure that your operations run smoothly and effectively.

User Interface

A user-friendly interface can significantly reduce the learning curve and increase adoption amongst your team, making it easier for them to embrace new technology.

Look for intuitive systems that not only simplify daily tasks but also offer comprehensive training and ongoing support. Such systems empower your team to maximize productivity and efficiency, ensuring a smoother transition and more consistent use across your organization.

Cost

It’s crucial to consider various financial aspects such as upfront costs, subscription fees, and potential return on investment (ROI). These factors should be carefully weighed against the benefits and efficiencies that the WMS will provide to your operations. Additionally, it is essential to look for a system that offers scalable pricing options. As your business requirements and operational needs evolve, the system should have the ability to grow with you, allowing for cost adjustments that align with your expanding needs. This ensures that the WMS remains a valuable and cost-effective tool over time.

Top Warehouse Management Systems of 2024

System 1: Lofko

Overview: Lofko System is celebrated for its sophisticated capabilities to streamline inventory management, making it the top choice for small to medium-sized businesses aiming for efficient stock control. With intuitive features and detailed tracking, it empowers businesses to streamline processes, minimize errors, and optimize inventory levels to effectively satisfy customer demands.

Best For: Small businesses and ecommerce brands.

Key Features:

- Real-time inventory tracking

- Add functionality as required

- Intuitive user interface

Pros and Cons:

- Pros: Lofko System is incredibly adaptable, allowing you to add additional functionality as needed. It is especially favoured by rapidly growing ecommerce businesses that require technology capable of scaling with their growth. It also integrates seamlessly into larger ERP ecosystems to provide specialized functionality.

- Cons: The software, although packed with many functions to assist your supply chain demands, may not be as robust as other software. This comes down to knowing exactly what your business needs and if Lofko will service that. They offer a FREE 45-minute strategy call.

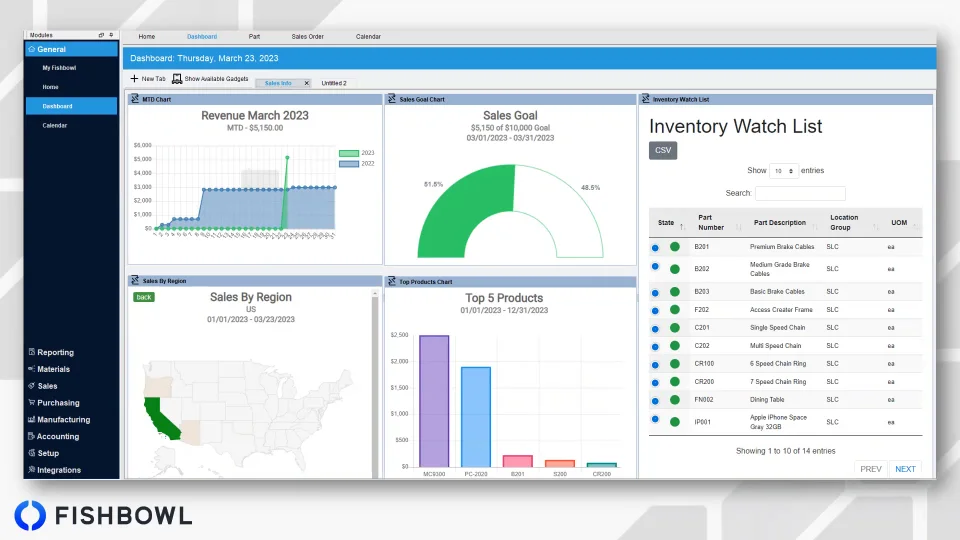

System 2: Fishbowl Warehouse

Overview: Fishbowl Warehouse is renowned for its robust warehouse management software, making it an ideal choice for small to medium-sized businesses seeking efficient stock control. With user-friendly features and comprehensive tracking, it helps businesses streamline operations, reduce errors, and optimize inventory levels to meet customer demands effectively.

Best For: Small businesses and ecommerce brands.

Key Features:

- Real-time inventory updates

- Integration with QuickBooks

- Advanced reporting tools

Pros and Cons:

- Pros: The product is affordable, making it accessible to a wide range of customers. Additionally, it comes with excellent customer support, ensuring that users have access to assistance whenever they need it.

- Cons: While the product is suitable for small to medium-sized businesses, its scalability is limited when it comes to supporting very large operations, which may require more robust solutions.

System 3: NetSuite WMS

Overview: NetSuite WMS provides a comprehensive suite of tools specifically designed for larger enterprises to efficiently manage their warehouse operations. It includes features such as inventory tracking, order fulfillment, and real-time data analytics, all of which help businesses optimize their supply chain processes and improve overall productivity.

Best For: Medium to large enterprises.

Key Features:

- Seamless integration with NetSuite ERP

- Advanced order fulfillment

- Real-time analytics

Pros and Cons:

- Pros: The product is highly customizable, allowing users to tailor it to their specific needs and preferences. It also offers an extensive feature set, providing a wide range of functionalities that can enhance user experience and efficiency.

- Cons: The higher cost can be a barrier for some potential users, as it requires a more significant investment. Additionally, the complex implementation process may necessitate additional time and resources to integrate seamlessly into existing systems.

System 4: Zoho Inventory

Overview: Zoho Inventory offers an easy-to-use platform at an affordable price, making it an ideal solution for small businesses looking to manage their inventory efficiently. With features such as order management, stock tracking, and integration with other Zoho apps, it helps streamline operations and improve overall productivity.

Best For: Startups and small businesses.

Key Features:

- Multi-channel selling

- Automated workflows

- Batch and expiry date tracking

Pros and Cons:

- Pros: The software is user-friendly, making it easy for individuals of all skill levels to navigate and use effectively. Additionally, it is affordable, offering great value for those on a budget.

- Cons: However, it has limited advanced features, which may not meet the needs of more experienced users seeking comprehensive tools for complex tasks.

System 5: SAP Warehouse Management (EWM)

Overview: SAP EWM provides a comprehensive suite of powerful tools designed to manage complex warehouse operations with efficiency and precision. Its robust features, such as advanced inventory management, task interleaving, and real-time data processing, make it a favourite among large enterprises seeking to optimize their supply chain and logistics processes. By leveraging SAP EWM, businesses can achieve greater operational visibility, streamline their workflows, and enhance overall productivity.

Best For: Large enterprises with complex needs.

Key Features:

- High-level automation

- Advanced labour management

- Real-time data processing

Pros and Cons:

- Pros: The system is highly efficient, providing quick and reliable performance across various operations. It is also scalable, meaning it can easily accommodate growth and handle increased loads over time.

- Cons: The system is quite expensive, which may be a significant consideration for smaller organizations or startups with limited budgets. Additionally, there is a steep learning curve involved, requiring substantial time and resources for team members to become proficient.

System 6: Odoo WMS

Overview: Odoo WMS combines flexibility with affordability, offering a modular approach to warehouse management that allows businesses to tailor their operations to specific needs. This system enables efficient tracking of inventory, streamlining processes, and optimising resource allocation, which results in cost savings and improved productivity.

Best For: Growing businesses and SMEs.

Key Features:

- Modular system with customizable features

- Integration with Odoo’s suite of apps

- Real-time reporting

Pros and Cons:

- Pros: This solution is highly flexible, allowing users to adapt and modify it to fit their specific needs and requirements. It is also cost-effective, offering a financially viable option for many businesses and individuals seeking to maximize their resources.

- Cons: However, it requires a certain level of technical know-how for customization. Users need to have or acquire the necessary skills to effectively implement and adjust the system to their unique specifications.

What Are the Advantages of Implementing Warehouse Management Systems in eCommerce and Retail?

Implementing a Warehouse Management System (WMS) in eCommerce and retail can significantly boost operational efficiency and effectiveness, streamlining processes and enhancing customer satisfaction. Here are some key advantages:

Enhanced Inventory Management

- Precision: A WMS enables real-time tracking of inventory levels, drastically reducing errors like overstocking or stockouts. This precision helps businesses maintain optimal inventory, avoiding unnecessary costs and lost sales.

- Visibility: It offers comprehensive visibility of inventory across various locations, including stores, warehouses, and goods in transit. This transparency allows businesses to better coordinate across channels and quickly respond to market demands.

Improved Order Fulfillment

- Speed: By optimizing picking and packing processes, a WMS speeds up order processing, helping meet customer expectations for fast delivery—crucial in the competitive eCommerce world.

- Accuracy: It minimizes order fulfilment errors, ensuring customers receive the correct items promptly. This accuracy enhances customer experience while reducing costs tied to returns and refunds.

Optimized Warehouse Space

- Efficiency: A WMS supports intelligent inventory layout planning, maximizing warehouse space usage. By optimizing storage configurations, businesses can store more products without expanding their facilities.

- Cost Savings: By maximizing existing warehouse capacity, companies avoid the costs associated with additional storage space, lowering operational expenses.

Increased Labor Productivity

- Task Management: A WMS efficiently allocates labour, guiding workers through optimized picking routes, saving time and reducing fatigue. This leads to a more productive workforce and lowers labor costs.

- Performance Tracking: The system enables performance monitoring, offering data-driven insights to improve labour planning. Managers can identify improvement areas and provide targeted training.

Streamlined Returns Processing

- Efficiency: Automated WMS systems facilitate faster return processing, allowing quick restocking and inventory updates. This efficiency helps manage returns more effectively.

- Customer Satisfaction: Faster turnaround times on returns and exchanges enhance customer service, boosting satisfaction and loyalty.

Cost Reduction

- Inventory Costs: Improved inventory management with a WMS minimizes write-offs and reduces safety stock needs, lowering inventory costs.

- Operational Costs: Optimizing resource allocation and transportation routes reduces labour and shipping expenses, contributing to overall savings.

Enhanced Customer Satisfaction

- Reliability: Reliable order fulfilment through a WMS leads to fewer customer complaints and returns, fostering trust and encouraging repeat business.

- Engagement: Improved service levels lead to higher customer retention and loyalty, with satisfied customers more likely to recommend the business.

Scalability

- Flexibility: A WMS offers the flexibility to scale operations based on business growth or seasonal changes, ensuring seamless adaptation to demand fluctuations.

- Adaptability: The system can handle increased order volumes and additional product lines without significant infrastructure investments, supporting growth and expansion.

Better Decision Making

- Data-Driven Insights: A WMS delivers rich analytics and reporting, providing valuable insights for informed decision-making, from daily operations to long-term strategies.

- Forecasting: Enhanced demand forecasting and inventory and staffing adjustments enable businesses to proactively meet customer needs and optimize resources.

Advanced Features in Modern Warehouse Management Systems

Automation

Modern WMS systems integrate automation to streamline operations, reduce manual errors, and enhance productivity. Automated picking, packing, and sorting are examples of how automation can transform your warehouse.

Real-Time Analytics

Real-time data allows for rapid decision-making. Advanced WMS platforms offer real-time analytics, helping businesses forecast demand, optimize inventory levels, and improve overall efficiency.

Customization

Flexibility is key in today’s dynamic business environment. Many WMS platforms now offer high levels of customization, allowing businesses to tailor the system to their specific operational needs.

Cost and Pricing

How Much Does a Warehouse Management System Cost?

The cost of a warehouse management system (WMS) can vary widely, depending on several factors such as the size and complexity of the warehouse, the number of users, and the level of customization required. On average, businesses can expect to invest anywhere from $5,000 to $50,000 or more per year for a WMS. This investment can significantly enhance warehouse management, leading to improved efficiency and cost savings in the long run.

Factors Affecting WMS Pricing

Several factors can influence the pricing of a WMS, including:

- Size and Complexity of the Warehouse: Larger warehouses with more complex operations require advanced WMS features, which can increase the cost.

- Number of Users: The more users who need access to the WMS, the higher the cost, as licensing fees are often based on the number of users.

- Level of Customization: Customizing a WMS to meet the specific needs of a business can add to the overall cost. Tailored solutions often require additional development and integration work.

- Support and Maintenance: The cost of ongoing support and maintenance can vary depending on the level of service required. Comprehensive support packages may come at a premium but can ensure the system runs smoothly and efficiently.

Warehouse Management Systems for Specific Industries

E-commerce and Online Retail

E-commerce and online retail businesses have unique requirements when it comes to warehouse management. A WMS tailored for these industries must handle high volumes of orders and inventory efficiently. Key features to look for in a WMS for e-commerce and online retail include:

- Real-Time Inventory Tracking: Ensures that inventory levels are accurate and up-to-date, preventing stockouts and overstocking.

- Automated Order Fulfillment: Streamlines the order fulfilment process, reducing errors and speeding up delivery times.

- Integration with E-commerce Platforms: Enables seamless integration with online shopping platforms, ensuring a smooth flow of information and operations.

- Barcode Scanning: Enhances inventory tracking accuracy and reduces manual errors, improving overall efficiency.

Some popular WMS options for e-commerce and online retail include:

- Datapel WMS: Known for its robust inventory management and real-time tracking capabilities.

- NetSuite: Offers comprehensive features and seamless integration with other business systems.

- MYOB Acumatica: Provides advanced order fulfillment and inventory management tools.

- Cin7 Omni: Ideal for multi-channel selling and automated workflows.

- CartonCloud: Focuses on simplifying complex warehouse operations with user-friendly features.

These WMS options offer a range of functionalities that can help e-commerce and online retail businesses streamline their warehouse operations, improve inventory management, and reduce costs. By choosing the right WMS, businesses can optimize their warehouse operations and stay competitive in the fast-paced e-commerce landscape.

Implementing Your Chosen Warehouse Management Systems

Steps to Take Before Implementation

Preparation is crucial for a smooth transition. Begin by mapping out your warehouse processes, identifying key areas that need improvement, and setting clear objectives for what you want to achieve with your new WMS.

Common Pitfalls and How to Avoid Them

Avoid common pitfalls such as insufficient training or underestimating the time required for a full implementation. Ensure your team is well-trained and allocate ample time for testing and adjustments.

Conclusion

Investing in the right WMS is crucial for enhancing warehouse efficiency and maintaining a competitive edge. Carefully evaluate each system’s features and ensure compatibility with your business needs to make an informed decision. Explore the top WMS providers and see which one aligns best with your operational goals.

Ready to take the next step? Schedule a demo with one of the top WMS providers to experience their capabilities firsthand. For more insights on optimising warehouse management, check out our comprehensive guides and resources.

If you would like us to assess whether our software solution would be a valuable addition to your business, you can book a free consultation call with our team HERE.