Boost Order Accuracy: 7 Effective Strategies for Your Business

21 Nov 2024

|by diadmin

Order Accuracy

In today’s eCommerce-driven world, order accuracy is crucial. Customers have endless options, and with every click, they expect the right item in the right quantity to show up on their doorstep. Failing to meet those expectations leads to a domino effect: operational inefficiencies, inventory management issues, unnecessary return processing, and increased shipping errors—all adding up to wasted time and money. For businesses, a single error is much more than a blip on the radar; it’s an expensive mistake that can erode customer loyalty and hurt the bottom line.

Retaining existing customers through enhanced order accuracy is essential. Delivering the right products consistently builds trust and reliability, which is crucial for customer loyalty and can lead to positive word-of-mouth marketing.

With the right approach, you can minimize mistakes, boost efficiency, and give customers precisely what they ordered. This guide covers seven game-changing strategies to improve your order accuracy. From optimizing your picking and packing process to implementing technology-driven solutions, these steps will help you meet—and exceed—customer expectations every time.

If you’re ready to stop losing customers over preventable errors and start fulfilling orders with precision, read on. High order accuracy isn’t just a goal; it’s your brand’s promise to deliver right, every time.

Understanding Order Accuracy

Order accuracy is the measure of how precisely a business fulfills a customer’s order, down to every last detail. It reflects how well the items shipped match the exact contents, quantities, and specifications requested by the customer. In simpler terms, order accuracy is about getting it right the first time—packing and delivering precisely what the customer ordered.

Achieving a high order accuracy rate is essential in today’s market with 88% of buyers say experience matters as much as a company’s products or services. Order accuracy doesn’t just enhance the customer experience—it also streamlines operations, reduces wasted resources, and allows businesses to stay competitive.

Definition of Order Accuracy

Order accuracy refers to the degree to which an order’s contents match the original order request from the customer. It measures how often a business correctly fulfills customer orders, accounting for aspects like correct items, quantities, and specifications.

Order accuracy is a critical metric for ecommerce merchants to determine the number of orders fulfilled and delivered to customers without errors. High order accuracy ensures that customers receive exactly what they ordered, which is fundamental for maintaining customer satisfaction and loyalty. In essence, achieving high order accuracy means consistently meeting customer expectations and minimizing the risk of incorrect orders.

Importance of order accuracy in the entire order fulfillment process

For customers, the experience of receiving the exact items they ordered is a basic expectation, but for businesses, meeting this expectation consistently is a powerful driver of customer loyalty, repeat business, and a positive brand reputation. Consistent order accuracy helps in retaining existing customers and building trust, which is crucial for long-term success.

Direct Impact on Customer Satisfaction and Loyalty

Inaccurate orders don’t just disappoint customers—they create frustration and negative perceptions that linger. A single incorrect order can drive a customer to rethink their relationship with your brand. High order accuracy, on the other hand, meets—and even exceeds—customer expectations, building a foundation for long-term customer loyalty.

Customers who receive exactly what they expect are more likely to leave positive reviews, recommend your business, and continue shopping with you, which boosts customer retention rates.

Operational Efficiency and Cost Savings

Poor order accuracy costs businesses in multiple ways. Each incorrect order means additional time and resources spent handling returns, processing refunds, or issuing replacements. These mistakes also disrupt inventory management, as returns and exchanges can cause inaccuracies in inventory records and increase handling costs.

By improving order accuracy, businesses reduce these extra costs, streamline their inventory management process, and free up resources for other critical fulfillment operations.

Enhanced Inventory Forecasting and Decision-Making

High order accuracy is closely linked to effective inventory management. Accurate orders provide a clear picture of real-time inventory data, reducing the risk of overstocking or stockouts.

With reliable order accuracy metrics, businesses can forecast inventory needs with greater precision, identify popular items, and make informed decisions on inventory replenishment. Accurate forecasting minimizes waste, optimizes stock levels, and ensures that the right items are always available to meet customer demands.

Competitive Advantage

Order accuracy is also a key difference in today’s competitive market. Businesses with consistently accurate order fulfillment avoid the competitive disadvantage of frequent order processing errors and the resulting negative reviews.

In industries where customers have numerous options, a reputation for reliability and accuracy can set your business apart, fostering trust and making your brand the go-to choice over competitors who struggle with fulfillment errors.

In short, order accuracy is essential for customer satisfaction, operational efficiency, and competitive advantage. It keeps customers happy, streamlines your operations, and enables informed decision-making—all critical factors for long-term success.

Calculating and Interpreting Order Accuracy

Lack of Adequate Technology

Without advanced technology, businesses are at a higher risk of order inaccuracies. Modern tools like barcode scanning systems and warehouse management systems (WMS) are designed to streamline the order fulfillment process, reduce human errors, and enable precise tracking of inventory.

Without these tools, businesses often rely on manual processes, which are both error-prone and difficult to scale. Manual data entry and tracking create ample opportunity for mistakes, from incorrect items to inaccurate quantities, impacting the entire order fulfillment process and resulting in customer dissatisfaction.

Order Complexity

The more complex an order, the greater the chance for errors. When orders include multiple items, custom configurations, or specific instructions, the picking and packing process becomes more detailed and prone to mistakes. With complex orders, it’s easier for items to be mispicked or mispacked, which can delay the fulfillment process.

In turn, these errors lead to shipping delays and costly corrections, which can hurt customer satisfaction. Complexity is a challenge that grows with business scale, as more products and order variations require even greater attention to detail.

Fragmented Sales Channels

Managing orders across multiple sales channels—such as a website, mobile app, and third-party marketplaces—introduces additional layers of complexity. Each channel may have different processes, timelines, and inventory requirements, making it harder to maintain order accuracy.

Fragmented channels increase the likelihood of errors during order processing, inventory tracking, and fulfillment. Misalignment between sales channels can also result in inaccurate inventory data, backorders, or overselling, which further disrupts the fulfillment process and can lead to negative customer perceptions.

Manual Order Processing

Relying on manual processes for order management introduces significant risks, particularly as order volumes increase. Human errors are inevitable in manual data entry, whether it’s during order entry, picking, packing, or shipping.

Manual order processing is also time-consuming, leading to slower fulfillment times, higher labour costs, and an increased chance of delays in processing and shipping. For businesses looking to scale, manual processes simply aren’t sustainable or efficient and are a common cause of incorrect orders and fulfillment errors.

How to calculate order accuracy rate

Here’s a step-by-step guide to measure order accuracy and evaluate how well your business fulfills customer orders:

- Count the Total Orders Fulfilled: First, get the total number of orders your business fulfilled over a specific period (like a day, week, or month).

- Identify the Total Accurate Orders: Next, count how many of those orders were fulfilled accurately. An accurate order is one where the customer received the correct items, in the right quantities, without any errors.

- Divide Accurate Orders by Total Orders: Take the number of accurate orders and divide it by the total number of orders fulfilled. This will give you a decimal representing your accuracy rate.

- Convert to a Percentage: Finally, multiply that decimal by 100 to turn it into a percentage. This percentage is your order accuracy rate.

What’s considered a good order accuracy rate?

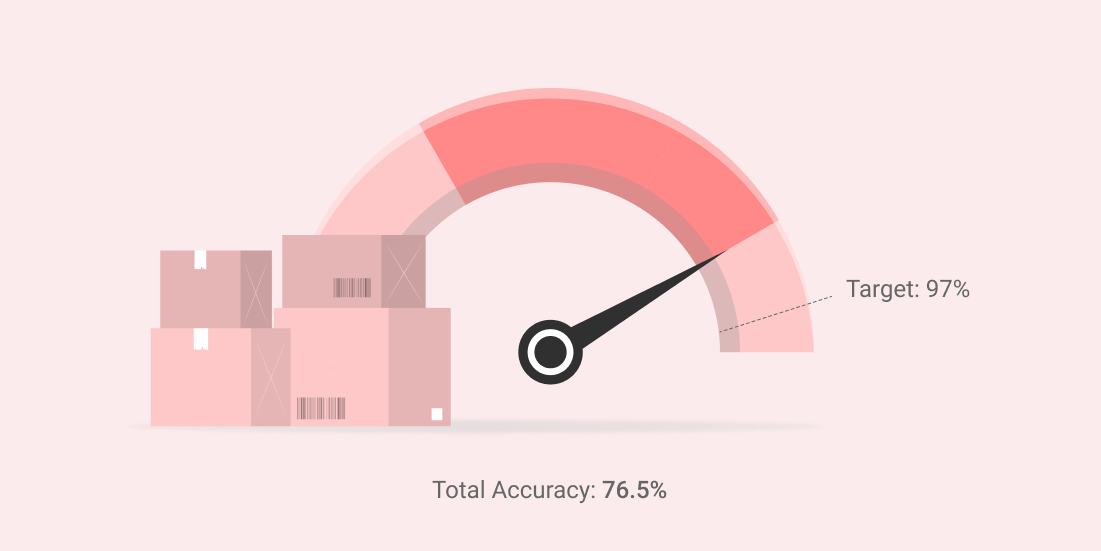

Achieving 100% order accuracy is an ambitious goal, and it’s challenging due to inevitable factors like human error and the complexity of the order fulfillment process. However, businesses should aim for an order accuracy rate between 96% and 98%, which is generally considered a strong score.

Hitting this range consistently indicates a well-optimized fulfillment process, where customers regularly receive the correct items and quantities with minimal errors. If your order accuracy rate falls to 95% or below, it’s often a signal that your fulfillment process has room for improvement.

How to interpret your order accuracy rate

Interpreting your order accuracy rate is crucial to understanding the effectiveness of your order fulfillment process. A high order accuracy rate indicates your business consistently delivers accurate orders to customers, which can lead to increased customer satisfaction, loyalty, and retention. Conversely, a low order accuracy rate can signal issues with your inventory management, picking and packing processes, or supply chain.

To interpret your order accuracy rate, you can use the following guidelines:

- 96-98%: An excellent order accuracy rate, indicating a high level of customer satisfaction and loyalty. This range suggests your inventory management and picking and packing processes are well-optimized.

- 90-95%: A good order accuracy rate, but with some room for improvement. This range indicates that while your processes are generally effective, there may be occasional errors that need to be addressed.

- Below 90%: A poor order accuracy rate, highlighting significant issues with your inventory management, picking and packing processes, or supply chain. This range suggests immediate action is needed to identify and rectify the underlying problems.

By regularly monitoring and analyzing your order accuracy rate, you can identify areas for improvement and implement strategies to increase customer satisfaction, loyalty, and retention. This proactive approach ensures your business remains competitive and capable of consistently meeting customer expectations.

7 Key Strategies to Improve Order Accuracy

Let’s explore seven practical strategies to boost your order accuracy, and how you can implement Lofko to ensure they are beneficial for your business’s success.

1. Set Clear Goals For Order Accuracy

Start by setting a realistic goal for your order accuracy rate. Analyze your current rate and aim to increase it if needed. Aiming for a 96-98% accuracy rate is an achievable target that aligns with industry standards and boosts customer satisfaction. Share this goal with your team and ensure everyone understands its importance in maintaining a smooth order fulfillment process.

How to Implement: Post your order accuracy target visibly in your fulfillment area to remind the team of this priority. Hold regular check-ins to discuss progress, celebrate milestones, and identify any issues affecting order accuracy. Encourage team members to feedback on where they see potential improvements.

2. Improve Inventory Management

A disorganized inventory can lead to mispicks and stock discrepancies that directly impact order accuracy. With Lofko’s all-in-one inventory management capabilities, you gain full visibility over stock levels and locations. Lofko’s real-time inventory tracking reduces the likelihood of errors, ensuring your team always works with accurate inventory data.

How to Implement: Use Lofko’s automated inventory tracking to update stock levels after each order is processed, keeping your records accurate. Lofko can also help you forecast demand based on order trends, allowing you to optimize stock levels and avoid both overstocking and stockouts.

3. Optimise Warehouse Organisation

A well-organized warehouse is essential for efficient picking and packing. With Lofko, you can organize your inventory effectively within the warehouse, setting clear zones for high-demand items and using warehouse slotting strategies that reduce time spent searching for items. Lofko’s warehouse management capabilities simplify navigation for employees, reducing the chance of picking errors.

How to Implement: Set up Lofko’s warehouse organization features to establish zones based on item popularity, grouping frequently ordered products closer to the packing stations. Use Lofko’s system to label bins and shelves, making it easier for your team to locate items accurately.

4. Use Automation Tools

Manual processes are prone to human error and slow fulfillment. Lofko’s automation capabilities handle tasks like order processing, inventory updates, and tracking, which frees your team from repetitive tasks and reduces the risk of mistakes. With Lofko, you can automate workflows across inventory, order, and warehouse management to streamline your order fulfillment process.

How to Implement: Start by automating inventory updates in Lofko, so stock levels are instantly adjusted after each transaction. Use Lofko’s order management system to automate order confirmations, tracking updates, and picking instructions. By eliminating manual tasks, you can improve order accuracy while increasing efficiency.

5. Optimizing the Picking and Packing Process

Picking and packing errors are common causes of order inaccuracies. Lofko’s pick and pack management tools streamline these processes, reducing the chance of human error. With features like batch picking and automated picking instructions, Lofko guides your team through each step of the order, ensuring that the correct items and quantities are selected every time.

How to Implement:

- For Picking: Enable batch picking within Lofko to group similar orders together, allowing your team to work more efficiently. Lofko’s picking instructions provide precise directions for staff, making it easy to find and select items accurately.

- For Packing: Use Lofko’s packing checklists to verify each item and quantity before shipping. Lofko’s quality control features ensure each order is double-checked before it leaves the warehouse, reducing errors and enhancing customer satisfaction.

6. Leveraging Technology for Order Fulfillment

A robust technology system is the backbone of a high-accuracy fulfillment process. Lofko integrates inventory, order, and warehouse management in one place, giving your team real-time visibility across the entire order fulfillment process. Lofko’s tracking features provide up-to-date information on order status, so you can identify any issues before they impact the customer experience.

How to Implement: Use Lofko’s barcode scanning and tracking features to reduce errors at every step, from inventory to final shipment. Lofko’s integration with ordering systems ensures data flows smoothly, so your inventory records, order status, and shipping updates are always accurate and synchronized.

7. Conduct Quality Checks

Quality checks help catch errors before they reach the customer. With Lofko’s quality control checkpoints, you can easily set up verification steps throughout the fulfillment process. Lofko’s system allows quality checks during picking, packing, and shipping, ensuring that each order is reviewed for accuracy before it goes out.

How to Implement: Set up quality checkpoints in Lofko at key stages, such as post-picking and pre-shipping. Use Lofko’s checklists to verify each item in the order, confirming correct quantities and item conditions. Reviewing data from these quality checks in Lofko also helps you spot errors trends, so you can proactively address any recurring issues.

Best Practices for Order Fulfillment

Implementing best practices for order fulfillment can significantly improve order accuracy, reduce errors, and increase efficiency. Here are three essential practices to prioritize for smoother operations and a more reliable fulfillment process.

Comprehensive training and development

Investing in comprehensive training and development ensures that each team member understands their role, follows standardized procedures, and knows how to handle tasks with accuracy and attention to detail. Proper training not only reduces errors in the picking and packing process but also boosts productivity and job satisfaction.

With ongoing development, staff can stay updated on new technologies and procedures that improve order accuracy. This commitment to training also leads to cost savings by reducing the number of order processing errors and minimizing the need for corrective actions.

Regularly reviewing and improving processes

By periodically assessing fulfillment processes, businesses can identify bottlenecks, spot inefficiencies, and address recurring issues. Process reviews ensure that each step, from inventory management to shipping, is optimized to reduce errors and maintain accuracy.

Regular process improvements also allow businesses to adapt quickly to changes, whether it’s a new product line, increased demand, or updated customer expectations. Over time, refining these processes contributes to higher order accuracy, reduced operational costs, and greater productivity across the fulfillment team.

Ensuring accurate inventory forecasting

Good forecasting enables businesses to make informed stocking decisions, so products are always available when needed, minimizing delays and improving order accuracy.

Reliable forecasts also reduce unnecessary costs associated with holding excess inventory or dealing with last-minute stockouts. By maintaining optimal inventory levels, businesses can keep fulfillment operations efficient, satisfy customer orders promptly, and avoid disruptions that impact customer satisfaction.

Measuring Success

To ensure your order fulfillment process stays efficient and accurate, it’s essential to track a few key metrics. Here are two simple but effective ways to measure success.

Tracking fulfillment KPIs

Monitoring key fulfillment KPIs—like order accuracy rate and picking accuracy—gives a clear picture of how well your fulfillment process is performing. These KPIs highlight areas for improvement, helping reduce errors, increase productivity, and lower costs over time.

Monitoring return rates and order cycle time

Keeping an eye on return rates and order cycle time is crucial for understanding customer satisfaction and fulfillment speed. High return rates can point to order accuracy issues, while a shorter order cycle time shows your process is efficient and fast. Both metrics help pinpoint where improvements can be made to ensure smoother, more accurate fulfillment.

Benefits of Improved Order Accuracy

Achieving high order accuracy brings a range of benefits that can transform both customer experience and business performance. Here’s how improved accuracy can positively impact your operations.

Cost Reduction

With fewer order errors, businesses save on costs associated with returns, reshipping, and customer service. These cost savings add up, reducing waste and freeing up resources for other areas. Greater accuracy also boosts productivity, enabling businesses to compete more effectively.

Enhanced Customer Satisfaction

Accurate orders lead to satisfied customers, which drives loyalty and repeat business. When customers receive exactly what they expect, they’re more likely to trust and return to your brand. This improved customer satisfaction strengthens retention, promotes positive reviews, and enhances brand reputation.

Operational Efficiency

High order accuracy streamlines the entire fulfillment process, boosting operational efficiency. By minimizing errors, your team can work faster and more effectively, reducing delays and increasing productivity. This efficiency not only saves costs but also gives your business a competitive edge in the market.

In short, investing in accuracy pays off by cutting costs, building customer loyalty, and making your operations smoother and more efficient.

Final Thoughts on Implementing Effective Strategies

Order accuracy is a critical factor in building customer satisfaction and loyalty. Accurate orders show customers that they can trust your brand, encouraging repeat business and positive word-of-mouth. Beyond customer experience, improved order accuracy also brings significant benefits for your operations—like cost savings, increased efficiency, and a competitive edge that sets you apart in the market.

By adopting effective strategies to boost order accuracy, businesses can minimize errors, enhance productivity, and reduce costs. These strategies support a smoother fulfillment process, helping you deliver consistently and reliably to customers. In the end, investing in order accuracy isn’t just about fulfilling orders; it’s about building a strong, efficient foundation that drives long-term success and competitiveness.

Frequently Asked Questions (FAQs)

1.What is order accuracy?

Order accuracy is a measure of how accurately a business fulfills customer orders, ensuring the correct items, quantities, and specifications are delivered as requested. High order accuracy improves customer satisfaction and loyalty by meeting customer expectations every time.

2. Why is order accuracy important in the order fulfilment process?

Order accuracy is essential for a smooth order fulfilment process because it reduces errors, minimizes returns, and builds trust with customers. Accurate orders help improve customer satisfaction, lower costs, and boost operational efficiency.

3. How can I improve order accuracy in my business?

Improving order accuracy can be achieved by using a warehouse management system (WMS), automating inventory management, and optimizing the picking and packing process. Regular training and reviewing fulfillment processes also help reduce human error.

4. How do I calculate the order accuracy rate?

The order accuracy rate can be calculated by dividing the number of accurate orders by the total orders fulfilled and then multiplying by 100. This gives a percentage that shows how often orders are fulfilled correctly.

If you need help, contact us!