How to Do Stock Taking: Easy Steps for Accurate Inventory Management

28 May 2025

|by diadmin

Stock taking is a critical process in inventory management, involving the physical checking and recording of all inventory. This ensures accurate records, reduces discrepancies, and prevents stockouts or overstocking. This article will show you how to do stock taking effectively, covering all essential steps from scheduling and preparation to conducting the count and updating your records.

Key Takeaways

-

Stocktaking is essential for accurate inventory management, helping to maintain precise records and prevent financial losses due to discrepancies.

-

Proper scheduling and organization of stock takes minimize disruptions to business operations, while defined roles and tools enhance efficiency.

-

Regular reviews and updates of inventory records post-stocktake are crucial for improving accuracy and optimizing future inventory management practices.

Understanding Stock Taking

Stocktaking involves physically checking and recording the entire inventory. This process is crucial in inventory management for maintaining accurate records, reducing discrepancies, and preventing overordering. But why is it so important? Imagine running out of a key product just when a customer needs it or overstocking items that don’t sell. These scenarios can lead to missed sales opportunities and financial losses.

Failing to conduct regular stocktakes can lead to outdated records and mismatches between your physical inventory and management system. Such discrepancies may conceal shrinkage due to theft or errors, resulting in significant losses over time. Maintaining accurate inventory records is key for effective planning and forecasting, allowing for informed decisions about sales, purchasing, and production.

Stocktaking helps businesses understand their inventory availability better, providing insights into which SKUs to reorder, their quantities, and the timing for reordering. Regular updates based on physical counts are necessary for maintaining total stock accuracy in a perpetual inventory system. This practice not only improves cash flow management but also enhances overall business decision-making.

Regular stocktakes help identify discrepancies quickly, enabling businesses to address issues immediately and avoid significant financial losses. Accurate stock levels allow businesses to optimize inventory management, prevent overordering, and reduce shrinkage.

Schedule Your Stock Take

Choose the right time for stocktaking to minimize disruptions to your business operations. The best times to conduct stocktakes are generally outside of trading hours or during periods of low business activity. This approach helps ensure a smoother process and reduces the impact on daily operations. Planning well in advance ensures that all resources and personnel are adequately prepared, minimizing disruption.

Consider staff availability when scheduling stocktakes. Confirm that enough stock takers are available by checking the roster, ensuring that the process is organized and runs smoothly. Choosing a date when business activities are low can further help in reducing the impact of stocktaking on operations.

Careful planning and scheduling of stocktakes can optimise inventory management and ensure accurate stock levels without causing unnecessary disruptions.

Prepare Your Stock Room

An organized stock room is the foundation of an accurate stocktake. Ensure the stock room is clean and well-organized to facilitate easy access to inventory items, minimizing errors and enhancing overall efficiency. Mapping out the stock room layout aids in efficient counting and helps staff understand their assigned areas.

Remove obsolete stock, set aside and label damaged inventory, and discard old boxes and excess materials to create a clean counting area. Good organization in the warehouse assists in stocktaking by making it easier to identify and access items.

Clearly label inventory items for quick identification. Designate specific areas for items in transit or reserved for customers to ensure accurate counts. Organizing stock in a logical manner can significantly streamline inventory control, making the counting process more efficient.

Gather Necessary Tools

Gather the right tools for a successful stock take, including pens, clipboards, calculators, stock sheets, and barcode scanners. Calculators are particularly crucial for manual stocktaking with large quantities. Utilizing barcode scanners can significantly enhance accuracy and speed during stock takes.

Prepare stock sheets to accommodate various data entry methods. Provide staff with clear instructions and necessary tools to ensure a successful inventory count.

Equip your team with the right tools and guidance to optimize the stocktaking process and ensure accurate results.

Assign Roles and Responsibilities

Clearly defined roles during stocktaking improve accuracy and organization. Assign specific duties such as a dedicated ‘counter’ and ‘recorder’ to streamline the process, ensuring each team member knows their responsibilities.

Ensure the staff roster has enough personnel for a successful count. Training on the tools used for stocktaking can reduce errors and improve results. Involving team members in the stocktake aids in identifying discrepancies and fosters accountability.

Inform the entire team about their roles to enhance organization and efficiency. Clear communication and defined responsibilities are key to a smooth and accurate stocktake.

Conducting the Physical Count

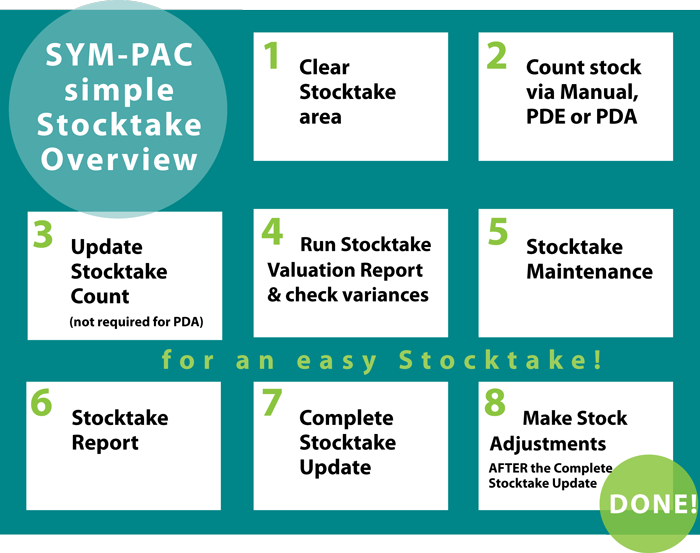

A physical inventory count involves predetermined methods to ensure accuracy, including manual, electronic, cycle counting, and full inventory counting. It’s recommended to count one type of inventory item at a time.

Conduct stock counts during closed hours to avoid confusion and maintain a steady process. Freeze inventory movements during a full physical count to prevent discrepancies. Reducing distractions improves speed and accuracy.

Electronic counting tools, such as scanners, significantly reduce errors compared to manual methods. Implement cyclical stocktakes to focus on smaller sections, reducing errors and time spent. Assign staff to specific locations within the inventory area to enhance efficiency and accuracy.

A well-prepared physical inventory count provides precise data essential for accurate financial reporting. Use scales for accurate counting of heavy inventory and consider having another person verify counts to improve accuracy.

Recording Inventory Data

Accurately recording inventory data is crucial for maintaining up-to-date records. Use a spreadsheet or accounting software depending on the number of stock lines and item complexity.

Start by listing some forbidden forms of the keyword “count stock” according to the rule 5. Keep current stock records to compare with new count stock. Avoid estimating inventory to prevent shortcuts and inaccuracies. Print and organize stock sheets in the right order before the count to streamline the process.

Accurate recording of inventory data optimizes management and ensures stock levels remain up to date.

Checking for Discrepancies

After completing a physical inventory count, compare the figures against records to identify discrepancies. Check for variances and conduct a recount if necessary, particularly for mismatched items. Investigate discrepancies as they may indicate theft, incorrect labeling, or human error.

Discrepancies signify differences between actual and recorded stock amounts, including unaccounted stock variance. Follow up on major and minor discrepancies to identify root causes and implement preventive measures.

Discrepancies in inventory data can indicate mistakes in tracking systems.

Updating Inventory Records

Accurate inventory records are crucial for preventing errors during stocktaking and ensuring effective stock management. Immediately update records to align with physical counts after completing the stocktake. Resolve discrepancies found during the stocktake to ensure that inventory records reflect true available stock.

Utilize automated systems to enhance the efficiency of updating inventory records post-stocktake. Keeping records up to date optimizes stock management and prevents overordering or stockouts with a stock control system and an inventory management system.

Continuous Improvement

Post-stocktake reviews identify inaccuracies and guide future improvements. Discrepancies can reveal weaknesses in operational processes. Regular stocktakes help prevent overstocking by providing a clear view of actual inventory levels.

Regular audits throughout the year simplify the stocktaking process by ensuring records are consistently updated. Encourage feedback and suggest improvements to evolve the process. Technology assists in optimizing the process and enables year-round inventory tracking.

Continuously improving the stocktaking process enhances overall inventory management processes and ensures accurate stock levels.

Summary

Accurate stocktaking is essential for effective inventory management. By understanding the importance of stocktaking, scheduling it properly, preparing your stock room, gathering necessary tools, assigning roles, conducting the physical count, recording data, checking for discrepancies, and updating records, you can ensure precise inventory management.

Implementing continuous improvement practices will help you refine your stocktaking process and improve overall inventory control. Take these steps to optimize your stock management and keep your business running smoothly.

Frequently Asked Questions

What is the formula for stock taking?

The formula for stock taking is =SUM(Stock Price*Quantity), which helps you calculate the running total of items in your inventory for effective tracking. This ensures you have a clear understanding of your stock on hand.

Why is regular stocktaking important for inventory management?

Regular stocktaking is essential for maintaining accurate inventory records and minimizing discrepancies, which ultimately leads to better decision-making in sales, purchasing, and production. This practice prevents overordering and ensures that inventory levels reflect current needs.

When is the best time to schedule a stocktake?

The best time to schedule a stocktake is outside of trading hours or during low business activity to minimize disruption. Proper planning and ensuring staff availability are essential for a smooth process.

What tools are essential for effective stocktaking?

For effective stocktaking, essential tools include pens, clipboards, calculators, stock sheets, and barcode scanners, as they enhance accuracy and efficiency. Utilizing these tools will streamline your stocktake process significantly.

How should discrepancies found during stocktaking be handled?

Discrepancies during stocktaking should be thoroughly investigated to determine their root causes, such as theft or human error. Addressing both major and minor variances is essential to prevent future issues.