Mastering Back Orders: A Comprehensive Guide to Management and Solutions

30 Oct 2024

|by diadmin

Back orders are one of those double-edged swords in the world of ecommerce. On the one hand, they can signal high demand and popularity for a product, but on the other hand, they risk leaving your customers waiting and frustrated. If you’re running an ecommerce business, back orders are almost inevitable, but how you handle them makes all the difference. It is crucial to inform customers about back orders and provide updates on order status, estimated fulfilment, and shipping dates to reassure them about the situation.

Let’s dive into the causes of back orders, the challenges they bring, and more importantly, how to manage them effectively using the right strategies and tools.

Understanding Back Orders

First, let’s break down what a backorder actually is. A backorder happens when a product is out of stock but still available for purchase, with the promise of future delivery once the inventory is replenished. This is different from out of stock items, which are unavailable for sale with no expected replenishment date. It allows you to keep selling, which is great for cash flow, but it also requires careful management to keep customers happy. When done right, accepting backorders can prevent lost sales. But mismanaged? You risk disappointing customers and losing their trust.

How Long Do Back Orders Take?

A question every ecommerce business owner has asked at some point. The truth is, there’s no one-size-fits-all answer. How long backorders take depends on several factors—supply chain speed, manufacturer lead times, and the availability of raw materials, to name a few. Supply chains, currently facing challenges due to disruptions from the COVID-19 pandemic and further complicated by environmental factors and global conflicts, significantly impact the duration of backorders. Sometimes, a backorder can be resolved in days; other times, it stretches into weeks.

Why Do Back Orders Happen?

Backorders happen for a variety of reasons, and as an ecommerce business owner, it’s crucial to identify why they’re happening to you. Here are the most common causes:

Unusual Demand

Ever had a product featured in a blog or on social media by a celebrity? Suddenly, it feels like your store exploded overnight. That rush of orders is thrilling but can wipe out your inventory faster than you can replenish it, leading to backorders. While the boost in sales is exciting, it can put immense pressure on your supply chain.

For ecommerce businesses, especially those using fulfillment tools, tracking real-time inventory is essential. By leveraging data analytics, you can prepare for spikes in demand and ensure you have the stock levels to meet customer expectations.

Low Safety Stock

Safety stock is your insurance policy against supply chain disruptions or unexpected sales spikes. If you haven’t set enough safety stock—or worse, if you don’t have any at all—you’re walking a tightrope. Running out of stock means back orders or, worse, cancelled orders.

Smart inventory management tools can help ecommerce businesses calculate and maintain optimal levels of safety stock, avoiding costly stock outs and the resulting back orders.

Supplier and Manufacturer Delays

Even the most organized ecommerce businesses can’t escape supply chain issues. Whether your supplier can’t deliver materials on time, or your manufacturer is behind schedule, external factors can cause significant delays in product availability. This, of course, leads to back orders.

One way to minimize the risk is by diversifying your supply chain. Ecommerce business owners can benefit from tools that integrate multiple suppliers, allowing you to switch quickly if one falls short. Having visibility into your suppliers’ timelines and setting realistic estimated delivery dates for your customers can save you a lot of headaches.

The Benefits Of Back Orders

While back orders might seem like an operational headache, there are some surprising upsides if you play your cards right. Backorders can help manage out of stock items by allowing sales to continue even when inventory is low, preventing customer loss to competitors.

More Efficient Use of Storage Space

Managing inventory means managing space, and backorders can actually help streamline your operations. When items are back ordered, they don’t sit around in your warehouse collecting dust. Once stock arrives, it goes straight to fulfilling customer orders, which means you can manage inventory turnover more efficiently.

For ecommerce business owners using fulfillment tools, this can also mean lower warehousing costs. Less time sitting in storage means lower warehousing costs and more agile inventory management.

Increased Cash Flow

This is a big one. Backorders allow you to keep bringing in cash, even if the product isn’t physically available. For many ecommerce businesses, this immediate cash influx can be crucial for covering operational costs, placing new orders, or expanding your product lines.

Tracking the financial impact of backorders through your ecommerce platform helps you understand how much cash flow is tied up in back ordered sales and helps plan better for future inventory needs.

Perceived Product Value

It sounds counterintuitive, but when customers see that a product is back ordered, it can actually signal that the product is in high demand. It creates a sense of urgency and exclusivity—sometimes prompting customers to hit “buy now” just to secure their spot in line. If managed well, backorders can create a buzz around your products and enhance their perceived value.

Best Practices for Back Order Management

Managing backorders is one thing, but doing it in a way that strengthens your relationship with customers? That’s next-level. Let’s explore a few best practices that can turn backorders into a moment of opportunity for your business.

Set Clear Expectations

Nothing frustrates customers more than uncertainty. If a product is back ordered, make it crystal clear on your website. Don’t bury the information in fine print—be upfront about the status of the item and the expected timeline. Customers appreciate transparency, and setting clear expectations helps prevent disappointment.

This is where a good inventory management system (we will touch on this below) becomes your best friend. It can automate notifications and update product pages in real time, so customers always know where they stand. By giving them accurate estimated delivery dates upfront, you’re building trust from the very start.

Build Excitement, Not Anxiety

Backorders can leave customers in limbo, which risks turning their excitement into frustration. To counter this, keep the momentum going by building excitement throughout the waiting period. Send personalized updates, share behind-the-scenes looks at the production process, or offer small incentives, like discount codes for their next purchase.

I’ve seen ecommerce businesses use this waiting period to create anticipation—almost like a pre-release for the product. By framing the delay as an exclusive opportunity to get in early, you keep customers engaged and eager. And that engagement can turn into customer loyalty down the road.

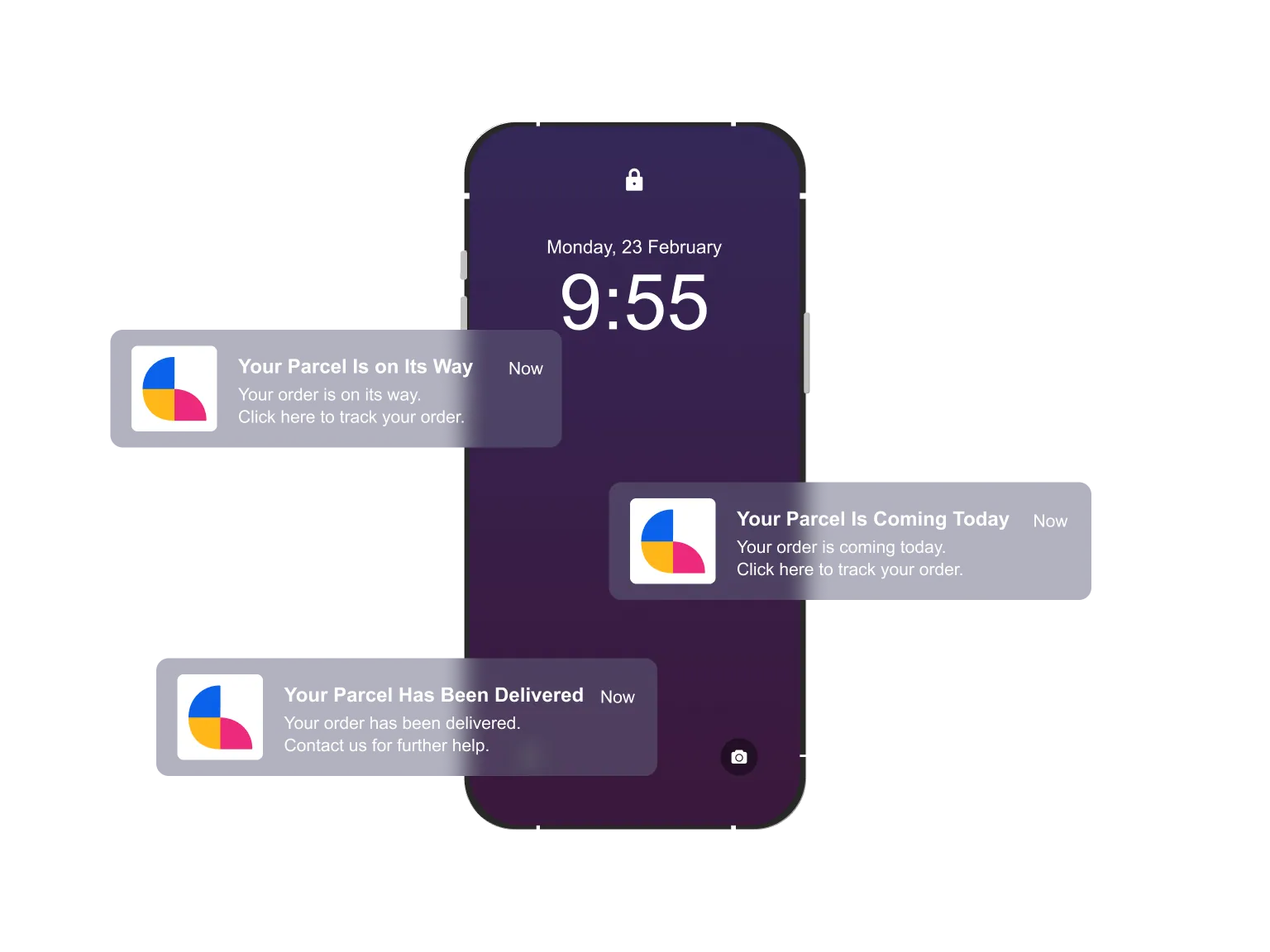

Stay in Touch Throughout the Process

The moment an order is placed, the clock starts ticking in your customer’s mind. Stay ahead of their expectations by regularly updating them on the order’s status. Send an email when their back ordered item is being prepared for shipment and let them know once it’s shipped. Even if nothing new happens, check in. A simple, “We haven’t forgotten about you!” goes a long way.

For ecommerce businesses, automation tools integrated into fulfillment platforms can make this process seamless. You don’t have to manually send each update—your system can handle it, ensuring customers always feel informed and valued.

How to Manage Back Orders Effectively

Now that we’ve covered why backorders happen and the potential upsides, the question is: how do you manage them without losing customers in the process?

It is crucial to inform customers about backorders by communicating vital updates regarding their order status, estimated fulfilment and shipping dates, and providing reassurance about the situation.

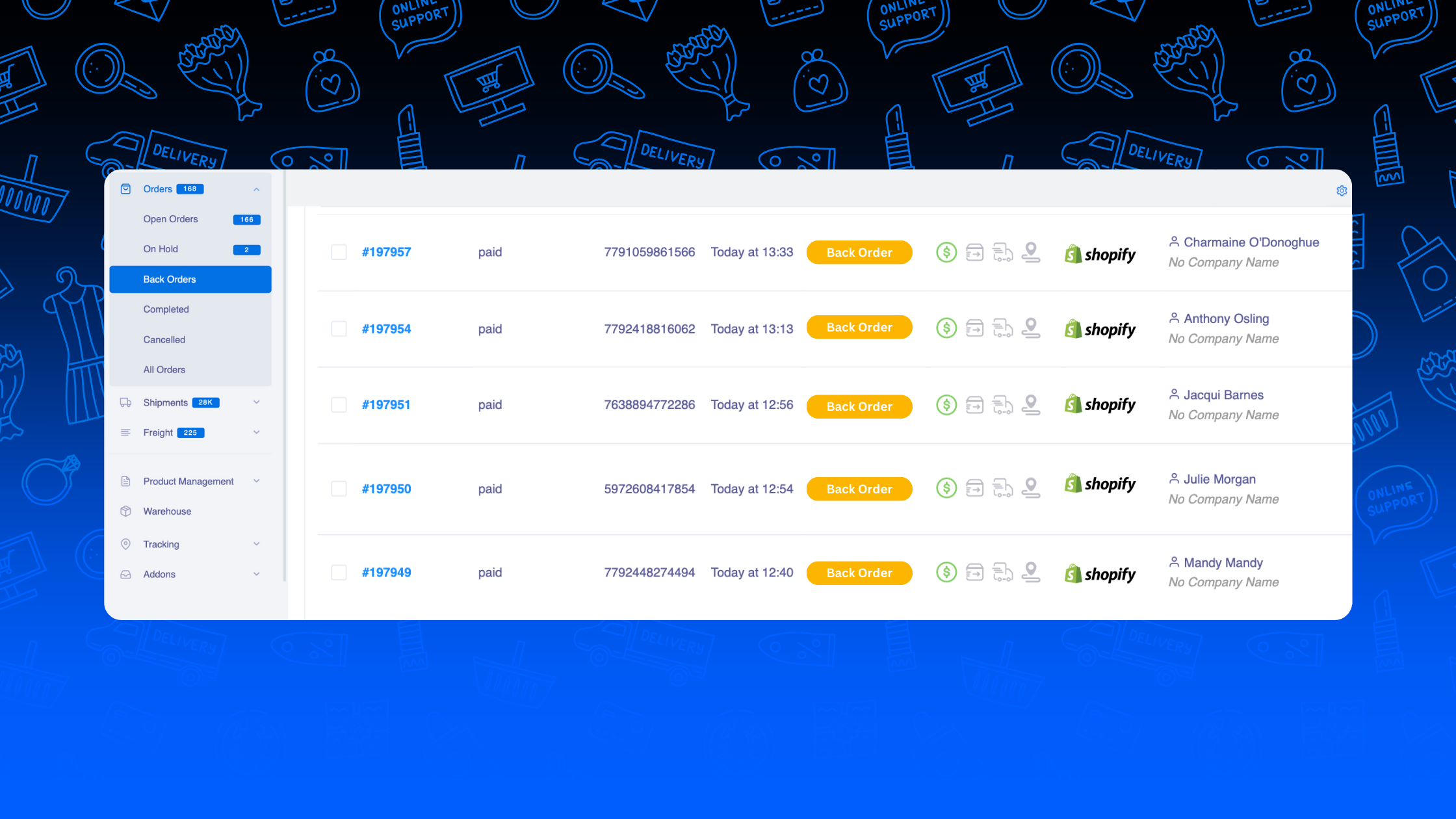

Use Smart Inventory Management Tools

You can’t avoid backorders entirely, but you can certainly reduce their frequency by staying on top of your inventory. Implementing a robust inventory management system (IMS) such as Lofko allows you to track stock levels in real-time, set reorder points, and maintain safety stock. These systems take the guesswork out of managing inventory and can even forecast future demand, helping you avoid potential stockouts.

For example, if you’re using a fulfilment tool like Lofko that integrates with your ecommerce platform, it can automatically notify you when stock levels are low and reorder products before you run into issues.

Keep Your Customers Informed

Communication is everything when it comes to backorders. Once a product goes on backorder, don’t leave your customers in the dark. Send out clear notifications about the backorder status and provide realistic estimated delivery dates. If there’s a delay, tell them. Transparency builds trust, and even though they might be waiting longer than expected, they’ll appreciate being kept in the loop.

Offering features like email notifications when a product is back in stock or when a back ordered product is shipped helps smooth the customer experience and keeps their trust intact.

Offer Alternatives

Sometimes, the best way to manage backorders is by offering alternative products. If a customer’s order is delayed, give them the option to choose a similar item that’s in stock. Not only does this satisfy their immediate needs, but it also shows that you’re proactive and value their business.

Ecommerce fulfillment tools should have the flexibility to automatically suggest these alternatives, based on stock availability. Ask Us How!

How to Reduce Back Order Risks

Reducing the risk of backorders isn’t just about keeping inventory stocked—it’s about smart planning and using the right tools to stay ahead of the game.

Diversify Suppliers

Don’t rely on just one supplier. Having multiple options allows you to switch quickly if one experiences delays. Using a fulfilment tool that can manage multiple suppliers in one platform gives you the flexibility to adapt to any supply chain hiccup.

Track Customer Demand

Analyzing trends in your sales data allows you to predict when demand will spike. Historical sales data, combined with smart forecasting tools, can give you the insights you need to stock up before the rush hits.

Cross-Docking and Just-in-Time Inventory

These advanced strategies help ensure that products move directly from suppliers to customers, bypassing warehouse storage. While it requires a robust system to manage, it can reduce the risk of stockouts and backorders.

Cross Docking and Back Orders Fulfillment

Cross-docking is a logistics strategy that can significantly enhance how ecommerce businesses handle back ordered items. By bypassing traditional warehousing, cross-docking allows products to move directly from the supplier to the customer, minimizing storage time and speeding up the fulfilment process.

For ecommerce businesses, this means that back ordered items can be processed and shipped much faster, reducing the waiting time for customers. When a product is back ordered, the last thing you want is for it to sit in a warehouse, adding unnecessary delays. Cross-docking streamlines this by ensuring that as soon as the product arrives from the supplier, it is immediately prepared for shipment to the customer.

Implementing cross-docking requires a robust inventory management system like Lofko that can handle real-time tracking and coordination between suppliers and shipping carriers. This system ensures that as soon as back ordered items are available, they are swiftly moved through the supply chain and into the hands of your customers.

By leveraging cross-docking, ecommerce businesses can not only improve the efficiency of their backorder fulfillment but also enhance customer satisfaction. Faster delivery times mean happier customers, which in turn can boost customer loyalty and repeat business.

Embrace Back Orders as a Learning Opportunity

Back orders might feel like a hassle at first, but for ecommerce businesses, they’re often a learning opportunity in disguise. They highlight gaps in your inventory planning, reveal new trends in customer demand, and, when managed well, build trust with your customer base.

With the right tools and strategies, backorders can become a moment where your business shines. It’s all about managing expectations, keeping your operations streamlined, and communicating with transparency. By following these best practices and leveraging smart fulfilment solutions, you can turn a potential pitfall into an opportunity to grow your brand and retain customers for the long haul.

FAQs

1. What is a backorder item?

A backorder item is a product that’s currently unavailable but can still be purchased, with the promise of delivery once it’s back in stock. Essentially, customers are placing an order for a product that’s temporarily out of stock but will be shipped at a later date.

For ecommerce businesses, this can be a smart way to keep sales rolling even during stock shortages. Just be sure you have a system in place to manage these orders efficiently and keep customers in the loop about product availability.

2. What does “on back order” mean?

When a product is “on backorder,” it means the customer is pre-ordering an item that is currently out of stock but expected to be available soon. It’s a way for your store to keep selling products even when supply is temporarily unavailable.

Using a reliable inventory management system allows you to track these back ordered products in real time, ensuring that you can deliver them to customers as soon as stock arrives.

3. How long do back orders typically take?

The length of a backorder depends on various factors, like supply chain issues, manufacturing delays, or even transportation hiccups. In some cases, it could be just a few days, but other times, backorders can take several weeks to fulfill.

This is where keeping customers informed is essential. Even if you don’t know the exact timeline, sharing a realistic estimated delivery date can help manage expectations and reduce frustration. Fulfilment tools that track supplier timelines can help you give your customers accurate updates.

4. What’s the difference between “back order” and “out of stock”?

“Out of stock” means a product is unavailable for purchase until inventory is replenished. Essentially, the “buy” button is disabled. With a backorder, the product is also unavailable, but customers can still place an order with the promise of delivery at a future date.

For ecommerce business owners, offering backorders helps capture sales that might otherwise be lost due to an “out of stock” status. However, managing backorders requires good communication and fulfilment strategies to make sure customers don’t get frustrated while they wait.

5. Are back orders good or bad for my business?

It depends on how you manage them. Backorders can actually be a great way to retain sales during inventory shortages. They’re also a sign of high demand, which can be a powerful marketing tool, showing that your products are in demand and worth waiting for.

However, if poorly managed, backorders can lead to unhappy customers, lost sales, and even damage your brand reputation. The key is having the right systems in place—like an inventory management tool—to track orders, communicate effectively, and fulfill backorders as soon as possible.

6. How can I prevent back orders?

The best way to avoid backorders is by implementing strong inventory management practices. Regularly monitor your stock levels, set accurate reorder points, and always maintain a buffer of safety stock for high-demand products. By using historical data and forecasting tools, you can better predict future demand and adjust your purchasing strategy accordingly.

Having multiple suppliers also helps minimize the risk of running into stockouts. If one supplier has delays, you have backups ready to step in and keep your operations running smoothly.