Inventory System for Small Business: Everything You Need To Know [Full Guide]

11 Oct 2024

|by diadmin

Inventory System for Small Business

What is Inventory Management?

Definition and purpose of inventory management

In sourcing the best inventory system for small business we need first to understand that inventory management is a crucial part of the supply chain, where an organisation systematically forecasts, procures, stores, consumes, and sells inventory alongside other supply chain stakeholders. This means that inventory management involves predicting the demand for products, acquiring the necessary inventory, storing it efficiently, using it when needed, and selling it to customers or other businesses. It is a complex process that requires careful planning and coordination with various partners in the supply chain. Effective managing inventory can streamline operations, reduce manual labour, and improve accuracy.

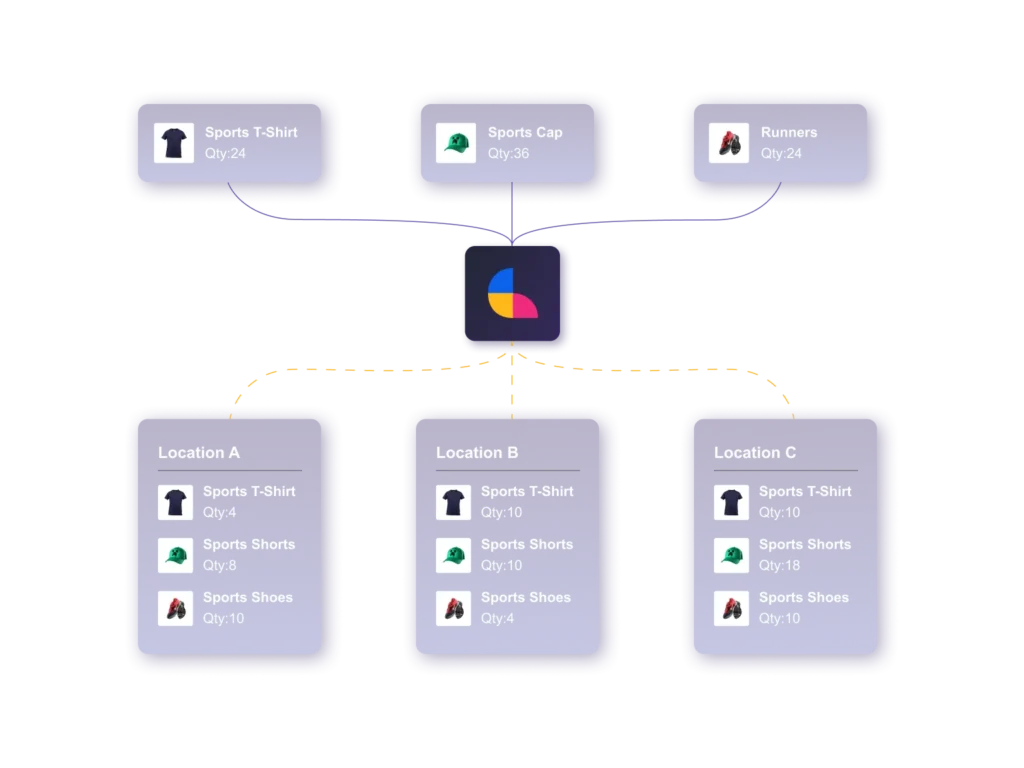

Inventory management software is available that solves small business challenges with solutions packaged and priced to suit an SMB’s budget. This means that there are software solutions specifically like Lofko, designed to help small and medium-sized businesses manage their inventory effectively. These software packages are tailored to the needs and budget constraints of smaller businesses, providing them with tools to streamline their inventory management processes and overcome common challenges.

Benefits of using an inventory system for small businesses

Inventory management software is a cornerstone for small businesses looking to enhance efficiency and boost profitability through better inventory control. Here are the primary benefits:

- Real-Time Inventory Tracking: Implementing an inventory system for small business allows for real-time inventory tracking, which is crucial for maintaining optimal inventory levels. This capability ensures that businesses can avoid excess inventory and out-of-stock scenarios, enabling them to manage inventory with greater accuracy and responsiveness.

- Customer Relationship Management: Effective customer relationship management (CRM) is essential for maintaining detailed customer records, enhancing customer service, and integrating seamlessly with vendor management. CRM tools are crucial for e-commerce businesses to manage customer interactions effectively and improve sales strategies through accurate inventory management and timely updates.

- Automation and Integration: The best inventory management software automates purchasing and order fulfilment processes, significantly reducing manual data entry and the likelihood of errors. Additionally, with robust integrations into accounting software, POS systems, and platforms like Zoho Inventory, businesses can streamline their operations across multiple sales channels and inventory locations.

- Enhanced Inventory Management Features: From barcode scanning to low stock alerts and detailed reports, advanced inventory management systems offer a range of tools that help businesses track and manage inventory more effectively. These features support everything from basic inventory tracking to complex supply chain management, including vendor management and inventory forecasting.

- Scalability and Customization: Whether it’s a small shop or a wholesale business with multiple warehouses, inventory management software can scale to meet growing needs. The flexibility to customize inventory processes and the availability of mobile apps for on-the-go management are key factors that make inventory software invaluable.

Cost-Effective Management Solutions: By optimizing inventory levels and streamlining operations, inventory management software helps small businesses minimize costs associated with storage and excess inventory. Moreover, many inventory solutions offer scalable pricing models, making them accessible for businesses of all sizes, from those needing basic inventory tracking to those requiring multi-warehouse management capabilities. However, it’s important to consider the inventory management software cost, as subscriptions can be quite expensive, potentially exceeding $300 per month depending on the complexity and features required.

Supporting Business Growth: With dedicated account management and the ability to sync inventory across online sales and physical retail spaces, the right inventory management tools serve as the backbone for business expansion. They not only improve inventory accuracy but also aid in critical areas such as sales forecasting and shipping management.

Lofko is an excellent choice for small businesses looking to enhance their inventory management. With its robust capability to provide real-time inventory tracking and seamless integration with various sales channels, Lofko simplifies complex processes and ensures accurate inventory control

Key features to look for in an inventory management system

Selecting the right inventory management system is crucial for enhancing efficiency and supporting growth. Small business inventory software is particularly beneficial as it helps in reducing inventory shrinkage and tracking stock movement effectively. Here are essential features that particularly benefit smaller enterprises:

- Total Product Traceability: Real-time tracking of stock through every step of the supply chain is critical for maximizing margins and minimizing disruptions. This feature not only manages product recalls efficiently but also boosts consumer trust through increased transparency.

- Multi-Channel Sales Support: Operating across multiple sales channels requires a synchronized system to manage inventory seamlessly. This feature ensures accurate inventory data across online and physical sales platforms, enhancing customer experience and preventing common inventory errors.

- Barcode Scanning: Integrating barcode and mobile scanners significantly boosts inventory accuracy. This technology streamlines processes such as shipment receipt and sales processing, greatly reducing manual errors and saving time, which is a boon for any resource-strapped business.

Challenges of Inventory Management for Small Businesses

Inventory management is a crucial aspect of running a small business, but it can also be a significant challenge. Small businesses often face unique inventory management challenges that can impact their bottom line and customer satisfaction.

Why inventory management is a challenge for small businesses

Small businesses often lack the resources and infrastructure to implement effective inventory management systems. This can lead to inaccurate inventory tracking, stockouts, and overstocking, which can result in lost sales and revenue. Additionally, small businesses may not have the expertise or personnel to manage inventory effectively, leading to inefficiencies and errors. Without a robust inventory tracking system for small business, these issues can compound, making it difficult to maintain optimal inventory levels and meet customer demands.

Industry-specific solutions for inventory management

Industry-specific solutions can help small businesses address unique inventory management challenges. For example, a retail business might benefit from a stock control software for small business that integrates with their POS system, providing real-time inventory tracking and sales data. On the other hand, a manufacturing business might need an inventory management system that offers detailed tracking of raw materials and finished goods. By leveraging industry-specific inventory management software, small businesses can tailor their inventory processes to better suit their operational needs and improve overall efficiency.

Common Mistakes to Avoid whilst Considering an Inventory Management System for Small Business

Effective inventory management is vital for your business’s efficiency and profitability. However, there are common pitfalls that can jeopardize your efforts. By recognizing these mistakes, you can steer clear of costly setbacks:

- Reliance on Spreadsheets: Are you still using spreadsheets to manage your inventory? If so, you’re likely familiar with the frustration of manual data entry errors. These inaccuracies can skew your inventory records and financial reporting, leading to decisions based on faulty data. By upgrading to a dedicated inventory management system, you can reduce these errors and ensure your data is both accurate and reliable.

- Uniform Stock Levels: Treating all inventory items with the same stock level approach can trap your business in a cycle of constant overstocking or understocking. Each product has its own demand pattern, and failing to recognise this can tie up capital or lead to missed sales opportunities. Implementing inventory management software that adjusts stock levels based on real-time sales data can dramatically improve your stock management efficiency.

- Irregular Inventory Checks: When was the last time you did a thorough inventory check? Infrequent checks can lead to unnoticed shrinkage and wastage—eating into your margins. Regular inventory audits and real-time tracking with an efficient inventory system ensure that you catch discrepancies early, keeping your operation lean and your cost management effective.

- Ignoring Inventory Shrinkage: Overlooking inventory shrinkage until it visibly impacts your bottom line is a risky oversight. This shrinkage, whether due to theft, damage, or mismanagement, directly translates into lost revenue. Establishing stringent inventory control and frequent monitoring can help mitigate these losses and safeguard your profits.

- Lack of Dynamic Pricing: Without dynamic pricing, you might be missing out on optimizing revenue based on changes in demand and stock levels. An inventory management tool that supports dynamic pricing can enable you to adjust prices dynamically, capitalizing on market demand and maximizing your profitability.

Avoid these common inventory management errors by adopting advanced tools that provide precise tracking, intelligent forecasting, and detailed reports. Doing so will not only streamline your inventory processes but also enhance your overall business operations, ensuring you are equipped to meet customer demand efficiently and profitably.

Implementing Inventory Management as a Small Business

| Step | Action Item | Description |

| Run a Vendor Audit | Conduct a Comprehensive Review | Evaluate current vendors and suppliers to understand their reliability, delivery, and quality. |

| Assess Vendor Performance | Regularly check vendor reliability, quality of goods, and responsiveness to maintain a strong supply chain. | |

| Identify Improvement Areas | Pinpoint gaps such as frequent delays, quality issues, or poor communication for improvement or vendor replacement. | |

| Streamline Ordering Processes | Evaluate Key Factors | Review consumption rates, storage capacity, reorder levels, and supplier lead times to maintain optimal inventory levels. |

| Implement Streamlined Processes | Develop an efficient ordering process to reduce errors and eliminate delays, ensuring smooth operations. | |

| Automate Purchasing and Fulfillment | Integrate automated systems to handle routine purchasing and order fulfilment tasks, enhancing accuracy. | |

| Implement Proper QA and Stock Receiving Protocols | Ensure Quality on Receipt | Inspect all received items to meet specifications before stocking to avoid future quality issues. |

| Set Up QA Protocols | Establish quality assurance protocols to maintain inventory accuracy and prevent customer complaints. | |

| Verify and Update Inventory Records | Accurately update inventory records upon goods receipt to keep reliable data for future planning. | |

| Perform Inventory Counting | Conduct Regular Counts | Regular checks ensure inventory records match the actual stock, aiding in quick discrepancy resolution. |

| Utilize Inventory Management Software | Use software tools to track inventory levels and movements, providing detailed insights and spotting anomalies. | |

| Verify Physical Stock | Periodically perform physical stock counts to confirm the accuracy between physical stock and digital records. |

Following this structured approach not only streamlines your inventory management process but also enhances overall operational efficiency. By implementing these steps, small businesses can achieve a more robust system that supports sustained growth and customer satisfaction.

Run a vendor audit

Running a vendor audit is an essential step in implementing effective inventory management. This involves evaluating vendors and suppliers based on their performance, pricing, and delivery times. Conducting a comprehensive review helps small businesses understand the reliability and quality of their suppliers, ensuring a strong supply chain. Regularly assessing vendor performance and identifying areas for improvement can lead to better vendor relationships and more consistent inventory levels.

Streamline ordering processes

Streamlining ordering processes is critical for effective inventory management. This involves evaluating consumption rates, storage capacity, reorder levels, and supplier lead times to ensure that inventory is ordered and received efficiently. Implementing streamlined processes reduces errors and eliminates delays, ensuring smooth operations. Automating purchasing and fulfilment tasks with inventory management software helps enhance accuracy and frees up valuable time for small business owners to focus on other critical aspects of their business.

By addressing these challenges and implementing industry-specific solutions, small businesses can improve their inventory management processes, leading to better operational efficiency and customer satisfaction.

Inventory Cycle Count and Reconciliation

What is the Inventory Cycle Count?

Inventory cycle counting is a streamlined alternative to full inventory audits, focusing on counting a small, specified portion of inventory on a regular basis rather than auditing the entire inventory at once. This approach allows businesses to continuously monitor and verify inventory accuracy without the disruption of a full inventory check.

Benefits of Inventory Cycle Counting:

- Identifies Discrepancies: Helps pinpoint errors and discrepancies in inventory records, enabling timely corrections.

- Ensures Continuous Accuracy: Regular checks ensure ongoing inventory accuracy, providing a clear picture of stock levels for better decision-making.

Inventory Cycle Count Methods

Implementing an effective cycle count procedure involves choosing a method that best aligns with your business objectives and operational dynamics. Common methods include:

- Random Sampling: Selecting items at random, ensuring that all inventory has an equal chance of being counted throughout the year.

- ABC Analysis: Dividing inventory into three categories (A, B, and C) based on value and frequency of use, with ‘A’ items counted more frequently.

- Control Group Counting: Regularly counting a fixed subset of inventory to quickly identify variations caused by procedural flaws.

Reconciling Inventory Differences: A 5-Step Guide

Properly reconciling inventory differences is crucial for maintaining accurate records and ensuring compliance. Here’s how to efficiently manage this process:

- Conduct a Physical Stock Count: Choose a counting method that best matches your business goals and regularly count different segments of your inventory.

- Assign Oversight Responsibilities: Designate a senior team member to oversee the counting process. This ensures accountability and improves the accuracy of the count.

- Verify Count Results: Use your inventory management software to compare the results of the physical count against your inventory records. This step is vital for identifying and understanding the scope of any discrepancies.

- Identify Discrepancies: Analyze the differences between the physical count and the inventory records to pinpoint specific areas of concern.

- Determine Causes and Write Offs: Investigate the causes of any discrepancies, such as shrinkage due to theft, damage, or administrative errors. Properly document and write off lost or unaccounted inventory according to accounting principles and compliance requirements.

Implementing a robust inventory cycle counting system not only helps in maintaining accurate inventory records but also supports better overall financial management and operational efficiency.

Choosing the Right Inventory System for Small Business System

Inventory Management Software Cost and Pricing:

When choosing an inventory management system, consider both the integration costs with existing systems and the software’s overall impact on your business operations. An effective system like Lofko offers competitive pricing with comprehensive functionality, ensuring you get a high return on your investment by optimizing inventory levels and reducing waste.

Integrations with Other Business Systems:

The right inventory management software should seamlessly integrate with other essential business systems such as accounting software and POS systems. Lofko ensures real-time updates of inventory levels and comprehensive tracking of items sold across different platforms, making it ideal for businesses that operate on multiple sales channels.

Ability to Track Items Sold in Different Places:

For businesses that sell inventory from multiple locations, it’s crucial to manage how much inventory is bought and replenished for each channel. Lofko excels in providing accurate, up-to-date information across all sales channels, enabling businesses to make informed decisions and meet customer demands efficiently.

Choosing Lofko as your inventory management system means opting for a solution that understands and adapts to the unique challenges of small businesses. With its robust features, seamless integrations, and dedicated support, Lofko is equipped to take charge of your inventory management requirements, letting you focus on growing your business.

Ready to see how Lofko can transform your inventory management? Book a demo with us today and take the first step towards optimised inventory control and business success.